Understanding Construction Vehicles: Essential Machines in Modern Construction 2024

In the ever-expanding landscape of urban development and infrastructure, construction projects play a pivotal role in shaping our modern world. From towering skyscrapers to extensive road networks and bridges, these projects are the backbone of economic growth and societal progress. However, behind every successful construction project lies a fleet of robust machines that facilitate the transformation of architectural blueprints into tangible structures.

Construction vehicles are the unsung heroes of the industry, providing the muscle and precision needed to complete complex tasks efficiently and safely. These versatile machines are designed to handle various demanding conditions, from excavating massive quantities of earth to transporting heavy materials across bustling work sites.

The purpose of this article is to delve into the diverse array of construction vehicles utilized in today’s industry. We will explore the different types of vehicles, their specific functions, and how they contribute to the overall efficiency and safety of construction projects. By understanding these essential machines, we can appreciate the innovation and engineering that drive modern construction and envision a future where construction continues to evolve and meet the ever-growing demands of society.

Types of Construction Vehicles

Construction vehicles come in various forms, each designed for specific tasks within a project. Below are some of the essential types of construction vehicles that play a vital role in the industry.

A. Excavators

- Description and Primary Functions

- Excavators are large, powerful machines equipped with a bucket at the end of a long arm (or boom). They are primarily used for digging, lifting, and transporting bulk materials.

- Their versatility allows them to perform tasks such as trenching, demolition, and site excavation effectively.

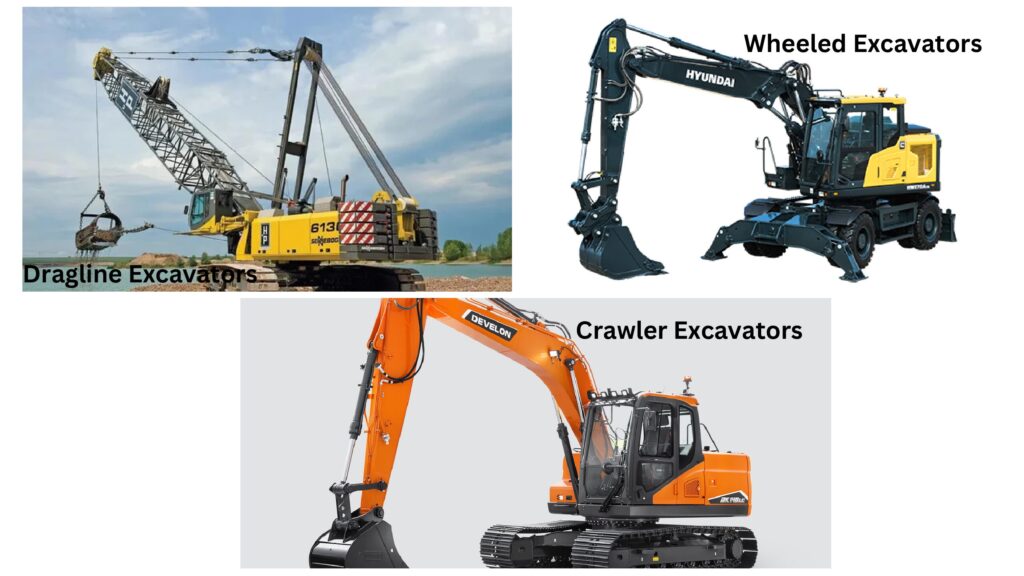

- Types of Excavators

- Crawler Excavators: These have tracks instead of wheels, providing enhanced stability and mobility across uneven terrain. They are ideal for heavy excavation work.

- Wheeled Excavators: These models offer greater mobility and can be used on paved surfaces. They are effective for urban projects and areas with less rough terrain.

- Dragline Excavators: Used for large-scale digging projects, these are equipped with a bucket that is dragged toward the machine, suitable for deep excavations.

B. Loaders

- Overview of Loaders in Construction

- Loaders are powerful vehicles designed to scoop, lift, and transport materials like gravel, sand, and dirt over short distances.

- They are commonly used in conjunction with other construction vehicles and are fundamental in most construction sites.

- Different Types of Loaders

- Skid-Steer Loaders: Compact and agile, these machines can maneuver in tight spaces and are often fitted with various attachments for different tasks.

- Backhoe Loaders: These versatile machines combine a loader on the front with an excavator arm at the back, making them suitable for digging and transporting materials in one unit.

- Wheel Loaders: Large and powerful, these loaders are capable of moving heavy loads and are often used for stockpiling and loading trucks.

C. Bulldozers

- Design and Features

- Bulldozers are equipped with a large, flat blade at the front that can push materials, making them essential for leveling and moving earth.

- Their tracked system provides stability, allowing them to operate on rough and uneven surfaces.

- Role in Site Preparation and Earthmoving

- Bulldozers are primarily used for site preparation, clearing land, and grade. Their robust design enables them to handle tough materials and push large quantities of earth with ease.

D. Dump Trucks

- Importance in Transporting Materials

- Dump trucks are crucial for transporting loose materials like soil, sand, and gravel from one location to another on construction sites.

- Their design allows for efficient unloading, which speeds up the workflow.

- Types of Dump Trucks

- Articulated Dump Trucks: These have a hinge between the cab and the dump box, granting greater maneuverability over rough terrain.

- Rigid Dump Trucks: Known for their durability, they are typically used for transporting heavier loads but are less maneuverable than articulated trucks.

- Transfer Dump Trucks: These feature a separate trailer that can be loaded with additional materials, expanding their capacity.

E. Cranes

- Use in Lifting and Moving Heavy Materials

- Cranes are essential for lifting heavy materials and equipment to elevated heights on construction sites, significantly enhancing the efficiency of material handling.

- Varieties of Cranes

- Tower cranes: These are fixed to the ground and known for their height and lifting capability, commonly used in tall building construction.

- Mobile Cranes: Highly flexible, these cranes can be moved easily between sites and are used for various lifting tasks.

- Rough Terrain Cranes: Equipped with large tires and powerful engines, these can navigate unpaved surfaces, making them ideal for sites where traditional cranes can’t operate.

F. Concrete Mixers

- Functionality and Importance in Constructions Involving Concrete

- Concrete mixers combine cement, aggregate, and water to produce concrete at construction sites.

- They are crucial for ensuring the concrete is mixed uniformly, allowing for better workability and structural integrity.

G. Graders and Scrapers

- Their Role in Leveling and Finishing

- Graders: Also known as motor graders, these machines have a long blade used for creating a flat surface, essential for road construction and final grading of sites.

- Scrapers: Designed for digging and transporting material, scrapers can cut, load, and carry soil or aggregates in one operation, making them efficient for large excavation projects.

H. Other Specialized Vehicles

- Pavers: Used for laying asphalt on roads, pavers are equipped with mechanisms to distribute, level, and compact the asphalt material smoothly.

- Trenchers: These machines dig trenches for installing utilities like

Technological Advancements in Construction Vehicles

The construction industry is experiencing a revolution fueled by technological advancements that enhance the capabilities, safety, and efficiency of construction vehicles. These innovations are reshaping how construction projects are executed and are enabling better outcomes for contractors and clients alike.

Automation and Remote Control

- Overview of Automation in Construction Vehicles

- Automation technologies in construction vehicles reduce the need for human operators, allowing machines to perform tasks with minimal manual intervention.

- Automated systems can include GPS and sensors that enable vehicles to operate in predefined patterns for tasks such as grading and excavation.

- Remote Control Technologies

- Remote-controlled vehicles allow operators to manage machinery from a distance, enhancing safety in hazardous environments.

- This capability is particularly beneficial in demolition, excavation, and hazardous material handling, reducing the risk of injury to operators.

Efficiency and Fuel Optimization Technologies

- Fuel Efficiency Innovations

- Modern construction vehicles are increasingly equipped with technologies that enhance fuel efficiency, such as hybrid and electric powertrains that reduce operational costs.

- Engine management systems optimize fuel consumption by adjusting parameters based on the vehicle’s workload and environmental conditions.

- Performance Monitoring Systems

- Telemetry systems track vehicle performance in real time, allowing for data-driven decisions regarding maintenance and operation.

- These systems help construction companies monitor fuel usage, identify inefficiencies, and schedule preventative maintenance, thereby extending the life of the machinery.

Safety Enhancements and Monitoring Systems

- Advanced Safety Features

- Many new construction vehicles come with advanced safety features such as collision avoidance systems, cameras, and sensors that monitor the surrounding environment to prevent accidents.

- Features like automatic braking or warning systems provide operators with critical information to enhance site safety.

- Operator Monitoring and Training Systems

- Systems that track operator performance can identify unsafe practices and provide feedback to improve skills and compliance with safety protocols.

- Virtual reality (VR) and augmented reality (AR) technologies are increasingly used for training, simulating real-world scenarios without the associated risks.

Integration with Building Information Modeling (BIM)

- Overview of BIM

- Building Information Modeling (BIM) is a digital platform that allows for the creation and management of a project’s information throughout its life cycle.

- Integrating construction vehicles with BIM provides real-time data on equipment usage and site progress, improving coordination among teams.

- Benefits of Integration

- By linking vehicle operations with BIM, construction firms can optimize logistics, manage equipment allocation, and predict project timelines more accurately.

- This integration enhances communication among stakeholders, enabling better decision-making and reducing the chances of costly errors.

Through these technological advancements, construction vehicles are becoming more efficient, safer, and integrated into the broader scope of construction management. As these technologies continue to evolve, they will drive further improvements in productivity and safety in the construction industry.

The Impact of Construction Vehicles on Project Efficiency

The integration of advanced construction vehicles into the construction process profoundly impacts project efficiency. By streamlining tasks, enhancing accuracy, and reducing labor requirements, these vehicles are reshaping how construction projects are executed. Below are key areas in which construction vehicles contribute to improved project efficiency.

A. Reduction in Time and Labor Costs

- Streamlined Operations

- Construction vehicles significantly increase the speed of various tasks, such as excavation, material transport, and site preparation. For example, the use of excavators and loaders can expedite the removal of large amounts of earth and debris, reducing the time required for grading and foundation laying.

- Automation technologies also contribute to time savings, allowing vehicles to operate continuously with minimal downtime for manual oversight.

- Decreased Labor Requirements

- With heavy machinery handling the bulk of physical labor, the need for large crews is reduced. This not only lowers labor costs but also minimizes the risks associated with having numerous workers on-site.

- Specialized equipment, such as automated dump trucks and remote-controlled cranes, reduces dependency on skilled human operators, enabling unskilled laborers to manage some tasks under supervision.

B. Improvement in Precision and Quality of Work

- Enhanced Accuracy

- Advanced construction vehicles equipped with GPS and laser-guided systems ensure precise execution of tasks. For instance, grading machines can achieve exact elevations, contributing to a level foundation for buildings and roadways.

- Excavators and bulldozers equipped with advanced sensors can minimize over-excavation and ensure that specifications are met with high accuracy, reducing material waste.

- Consistency in Results

- Automation technologies help maintain consistency across multiple tasks, resulting in uniform quality throughout the project. Regularized performance minimizes human error, leading to higher-quality workmanship.

- Vehicles designed for specific functions can achieve better performance in their designated tasks compared to manual methods, enhancing the overall quality of construction.

C. Case Studies Highlighting Successful Projects Aided by Advanced Construction Vehicles

- Large-Scale Infrastructure Projects

- A notable example is the construction of the Panama Canal expansion, where the use of advanced excavators and automated cranes allowed for efficient excavation and material handling, resulting in a significant reduction in project completion time.

- The project utilized a fleet of modern construction vehicles equipped with GPS technology that enabled precise excavation and helped monitor progress, leading to on-time delivery.

- Urban Development Projects

- In the development of the Hudson Yards in New York City, advanced loaders and dump trucks were employed to manage the significant amounts of material being relocated. The result was a project that met tight deadlines while maintaining safety standards, significantly impacting the urban skyline.

- The integration of BIM technology with construction vehicles in this project allowed for real-time monitoring of material usage and equipment, which optimized workflow and increased responsiveness to challenges.

- Residential Construction

- A recent residential development project in California showcased the benefits of using modern concrete mixers and pavers, which sped up the construction of roadways and foundations. The project saw a 20% reduction in labor hours due to the efficiency of the equipment used while maintaining high construction quality.

These examples underscore the critical role that construction vehicles play in enhancing project efficiency. By reducing time and labor costs, improving precision, and enabling successful project outcomes, these machines are indispensable assets in modern construction. Their continued evolution will likely yield even greater efficiencies in future projects.

Environmental Considerations

As the construction industry evolves, environmental considerations are becoming increasingly important. The impact of construction vehicles on the environment is significant, prompting the adoption of sustainable practices and technologies. Here’s an overview of the major environmental considerations related to construction vehicles.

A. Emissions and Carbon Footprint

- Impact on Air Quality

- Construction vehicles are significant contributors to air pollution due to emissions of nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and other harmful substances. These emissions can adversely affect air quality in urban and rural areas alike.

- Diesel engines, commonly used in heavy machinery, are particularly notorious for their high levels of harmful emissions.

- Carbon Footprint

- The carbon footprint associated with construction activities is considerable, largely due to the fuel consumption of construction vehicles. This has raised concerns about climate change and the need for sustainable practices.

- Efforts to calculate and reduce the carbon footprint of construction projects are becoming integral to project planning and execution, with a focus on lifecycle analysis and material sourcing.

B. Innovations in Sustainable and Green Technology

- Alternative Fuel Sources

- The use of alternative fuels such as biodiesel, natural gas, and hydrogen is gaining traction in the construction industry. These fuels produce fewer emissions compared to traditional diesel fuels and help to reduce the overall carbon footprint of construction vehicles.

- Electric and hybrid construction vehicles are also becoming more prevalent, offering zero or reduced emissions during operation. Many manufacturers are developing electric versions of excavators, loaders, and other essential machinery.

- Energy-Efficient Technologies

- Advanced technologies that improve energy efficiency in construction vehicles include regenerative braking systems, engine management systems, and hybrid powertrains. These systems optimize fuel consumption and reduce emissions.

- Additionally, the integration of telematics systems allows for real-time monitoring of vehicle performance, enabling operators to minimize fuel usage and emissions with data-driven insights.

- Sustainable Construction Practices

- The shift toward environmentally sustainable construction practices includes the adoption of materials and methods that have a lower environmental impact. This includes using recycled materials, reducing waste, and ensuring proper disposal of construction debris.

C. Regulatory Standards and Compliance

- Emissions Standards

- Regulatory agencies around the world are implementing stricter emissions standards for construction vehicles. In the United States, the Environmental Protection Agency (EPA) has established guidelines for diesel engine emissions, which have led to the development of cleaner engine technologies.

- The European Union has also put forth stringent regulations, including the Euro standards, which set limits on the emissions of new vehicles and equipment.

- Compliance and Incentives

- Compliance with environmental regulations is crucial for construction companies, often requiring investment in new technologies or fleet upgrades to meet emissions standards.

- Governments are also offering incentives, such as tax credits and grants, to encourage the adoption of cleaner technologies in the construction sector. Incentives for using electric vehicles or retrofitting older machinery can significantly reduce operational costs while promoting environmental sustainability.

In conclusion, addressing environmental considerations related to construction vehicles is essential for sustainable development in the industry. By focusing on reducing emissions, adopting innovative technologies, and adhering to regulatory standards, the construction sector can minimize its environmental impact while simultaneously improving project efficiency and compliance with modern sustainability practices.

Understanding the Slow-Moving Vehicle Symbol: Importance, Regulations, and Best Practices 2024

NITHIN FERNAND

Safety Standards and Operator Training

The construction industry is inherently risky, and the use of heavy machinery can exacerbate these risks if not managed properly. Ensuring the safety of workers and the efficiency of operations depends heavily on stringent safety standards and comprehensive operator training. Here’s an exploration of the key aspects related to safety on construction sites.

A. Safety Risks Associated with Construction Vehicles

- Operational Hazards

- The heavyweights and powerful machinery used in construction can pose significant dangers, including accidents related to equipment failure, improper operation, and collisions with other vehicles or personnel. Common incidents involve rollovers, falls, or being struck by moving equipment.

- Blind spots on larger vehicles can lead to accidents where operators may not see nearby workers, increasing the risk of collisions.

- Environmental Risks

- Construction sites often feature uneven terrain, loose materials, and changing conditions. These factors contribute to potential hazards associated with vehicle operation, including tip-overs and loss of vehicle control.

- Inadequate site management and planning can also lead to accidents, such as debris obstructing pathways or unmarked hazards.

- Health Risks

- Prolonged exposure to noise, vibration, and exhaust emissions from construction vehicles can lead to long-term health issues for operators, emphasizing the need for safety measures and protective equipment.

B. Importance of Operator Certification and Training

- Mandatory Certification Programs

- Many regions require operators to obtain certifications for operating specific types of machinery. These certifications ensure that operators possess the necessary skills and knowledge to safely handle construction vehicles.

- Organizations like the National Commission for the Certification of Crane Operators (NCCCO) and the Occupational Safety and Health Administration (OSHA) provide guidelines and assessments for operator training and certification.

- Comprehensive Training

- Operator training should cover various aspects, including safety protocols, equipment handling, emergency procedures, and maintenance checks. A well-trained operator is less likely to make errors that can lead to accidents.

- Training often includes hands-on experience, simulations, and classroom instruction, which together can significantly enhance a person’s confidence and ability to operate machinery safely.

- Continuous Education

- Ongoing training and refresher courses are essential in adapting to new technologies and regulatory changes. Continuous education helps ensure operators remain aware of the latest safety standards, operational best practices, and advances in vehicle technology.

C. Best Practices in Maintaining Safety on Construction Sites

- Implementing Safety Protocols

- Establish clear safety protocols and guidelines for the operation of construction vehicles. This includes daily safety checks, adherence to manufacturer instructions, and ensuring compliance with local regulations.

- Regularly review safety procedures with all workers to ensure everyone is aware of their responsibilities and the potential hazards.

- Site Safety Management

- Design a construction site layout that minimizes risks. This could involve clearly marked pathways for vehicles and personnel, designated loading and unloading zones, and areas for equipment storage.

- Use signage to communicate hazards, and ensure that all workers are aware of the site’s safety rules and emergency procedures.

- Protective Equipment and Safety Gear

- Require all personnel on site to wear appropriate personal protective equipment (PPE), such as helmets, gloves, high-visibility clothing, and safety boots.

- Install additional safety features on construction vehicles, such as backup alarms, cameras, and perimeter safety devices to protect nearby workers.

- Communication and Supervision

- Foster a culture of safety where open communication is encouraged among workers. Designate specific safety personnel or crew leaders to supervise operations and address safety concerns.

- Implement regular safety meetings to discuss potential hazards, recent accidents, and ways to mitigate risks, ensuring that safety remains a top priority.

In summary, maintaining high safety standards and providing thorough operator training are essential elements in mitigating risks associated with construction vehicles. By emphasizing certification, continuous education, and adopting best practices, the construction industry can significantly enhance safety outcomes and reduce the likelihood of accidents on job sites.

Conclusion

Construction vehicles are indispensable components of modern construction, playing a vital role in enhancing efficiency, safety, and sustainability across various projects. Their ability to streamline operations, reduce labor costs, and improve precision significantly contributes to the successful completion of complex tasks within set timelines and budgets. As the construction industry continues to evolve, the integration of advanced technologies and innovative practices remains crucial in further harnessing the potential of these machines.

Ongoing advancements in construction vehicles underscore the importance of adapting to new challenges and opportunities. Innovations such as autonomous machinery, electric vehicles, and eco-friendly fuel alternatives are reshaping the landscape, leading to more sustainable construction practices. These developments not only address the industry’s environmental impact but also enhance safety and operational efficiency, ultimately resulting in higher quality outcomes.

To navigate the future of construction effectively, it is imperative for industry stakeholders—ranging from operators and managers to policymakers and manufacturers—to commit to continuous innovation and adherence to best practices. This collaborative effort will ensure that the construction sector not only meets current demands but also sets higher standards for safety, environmental stewardship, and project efficiency.

In conclusion, the future of construction lies in our ability to leverage the full potential of construction vehicles while embracing advancements that promote sustainable and efficient practices. Industry leaders must champion this transformative journey by investing in technology, training, and safety standards, fostering a culture of excellence and responsibility within the construction community. Together, we can build a safer, greener, and more efficient future in construction.

References

- Heavy Equipment. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Heavy_equipment

- Construction Equipment Guide. (2023). Comprehensive Guide to Construction Trucks: Types & Uses. Retrieved from https://www.constructionequipmentguide.com/

- The Constructor. (2022). Essential Construction Vehicles and Their Uses and Functions. Retrieved from https://theconstructor.org/construction/essential-construction-vehicles/

- Construction Industry Research and Policy Institute. (2023). 23 Types of Construction Vehicles and What They Are For. Retrieved from https://www.cirpi.org/types-of-construction-vehicles/

- Equipment World. (2023). A Comprehensive Guide to Types of Construction Vehicles and Their Uses. Retrieved from https://www.equipmentworld.com/types-of-construction-vehicles/

- For Construction Pros. (2023). Exploring the Different Types of Construction Vehicles and Their Uses. Retrieved from https://www.forconstructionpros.com/

- World Economic Forum. (2023). Environmental Considerations and Construction Vehicles. Retrieved from https://www.weforum.org/agenda/environmental-considerations-in-construction-vehicles/

- Occupational Safety and Health Administration (OSHA). (2023). Safety Standards and Operator Training in Construction. Retrieved from https://www.osha.gov/standards

- Environmental Protection Agency (EPA). (2023). Innovations in Sustainable and Green Technology for Construction. Retrieved from https://www.epa.gov/sustainability-construction

- National Institute for Occupational Safety and Health (NIOSH). (2022). Safety Training for Construction Equipment Operators. Retrieved from https://www.cdc.gov/niosh/topics/construction/training.html

These references include reputable sources and articles related to construction vehicles, safety standards, environmental considerations, and innovations in technology. Adjust the links and formatting as needed to fulfill specific citation requirements.

FAQs

1) Which vehicle is used for building the most often?

Typical Construction Automobiles

1) The dump truck first. The dump truck is one of the most popular construction vehicles in any fleet

2) A bulldozer. The bulldozer is one of the most useful construction equipment when it comes to transporting dirt.

3) Skid-Steer Loader.

4) Backhoe.

5) The Crane.

6) The Bucket Truck.

7) Lifting by Air.

8) Trencher.

2) What is the best vehicle for construction?

pickup trucks